When companies self-assess their roofing systems, they often look at the surface and draw some fairly dramatic conclusions. The roofing industry has created scary terms such as; Blistering, ridges, alligatoring, mud curling and crazing, to describe typical membrane defects.

All these terms describe conditions occurring on the surface of a membrane. Although they may be a result of subsurface moisture, many of the issues are associated with environmental wear and the typical ageing process of the roof membrane.

Now here’s the thing about your roof system vs your roof membrane…

The roof membrane may only represent as little as 1% of the total volume of your entire roof system. Think about that for a second …would you throw away an entire wall assembly because the paint was flaking? Although that analogy borders on the absurd, there are some parallels.

One of the most common roof systems being installed on low-slope roofs over the last 15/20 years has been 2ply Modified Bitumen. The system has a granulated cap sheet with long seams, identifiable by a streak of bitumen that “bleeds out” from the laps.

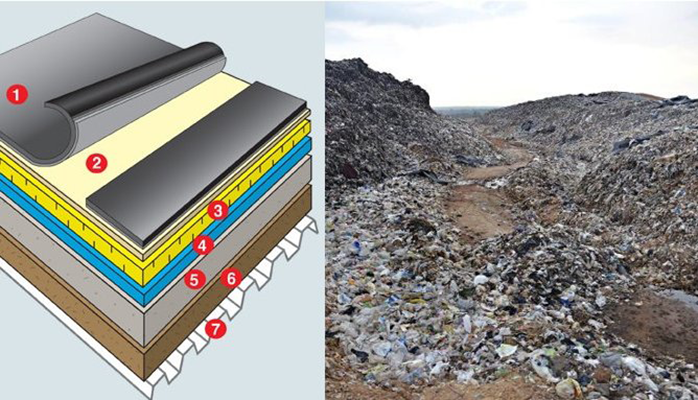

The surface membrane, or cap sheet, is approximately 4mm thick (.16”) and represents approximately 4% of the total volume of a typical roof system with an average thermal resistance of R20. As such, 96% of the roof system may very well be in good condition. Extending the service life of a low-slope roofing system is paramount in aiding in the reduction of greenhouse gas emissions as well as relieving the burden on our landfill sites. Most of the materials used to insulate low-slope roofs are non-biodegradable… and will remain, in “our” landfill sites for centuries.

Would you like more information on how to help save the planet while boosting your bottom line? Feel free to send me an email.